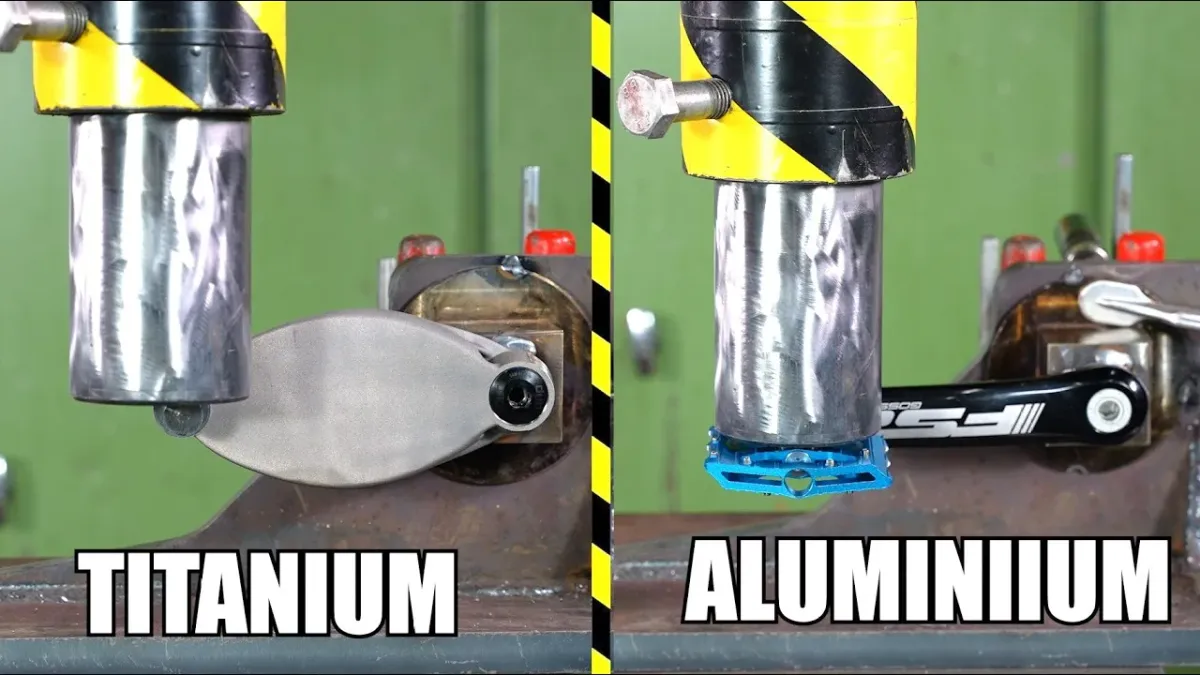

Hydraulic Press Channel puts 3D-Printed Titanium Bike cranks Up Against Forged Aluminum

Highly recommend this interesting and entertaining watch! Good to know that my “massive power” won’t be cracking my cranks anytime soon.

Welcome back to Hydraulic Press Channel – the place where metal meets its match! In today’s high-pressure episode, we’re meshing the realms of advanced 3D printing technology with the robust world of cycling. Witness the clash of the titans as topologically optimized bicycle cranks go head-to-head with their traditional forged counterparts. ♂️

— Hydraulic Press Channel

Using cutting-edge 3D printing and state-of-the-art topology optimization, we’ve engineered cranks that are built to withstand the ultimate test. Our 150 ton hydraulic press and 240 ton force sensor are ready to challenge the limits of materials science, and you’ll get to see if these next-gen cranks can outperform the classics in a battle of strength and endurance.

Will these optimized wonders revolutionize the way we think about bicycle crank durability? Tune in to see the power of technology push past the conventional, and discover why topology optimization could be the future of cycling components.