How RLS Disrupted Helmet Safety and Took the Top Spot at Virginia Tech

Discover RLS, the revolutionary helmet safety technology that just claimed the #1 and #2 spots in Virginia Tech's ratings. Learn how it works to reduce rotational forces and protect against brain injury.

For years, the conversation around advanced bicycle helmet safety has been dominated by a few key players and technologies, all striving to mitigate the dangerous rotational forces that can cause concussions. Now, a groundbreaking new system has not only entered the ring but has immediately claimed the top two spots in the world's most recognized independent helmet safety rankings. Meet the Release Layer System (RLS), a technology poised to redefine how we think about impact protection.

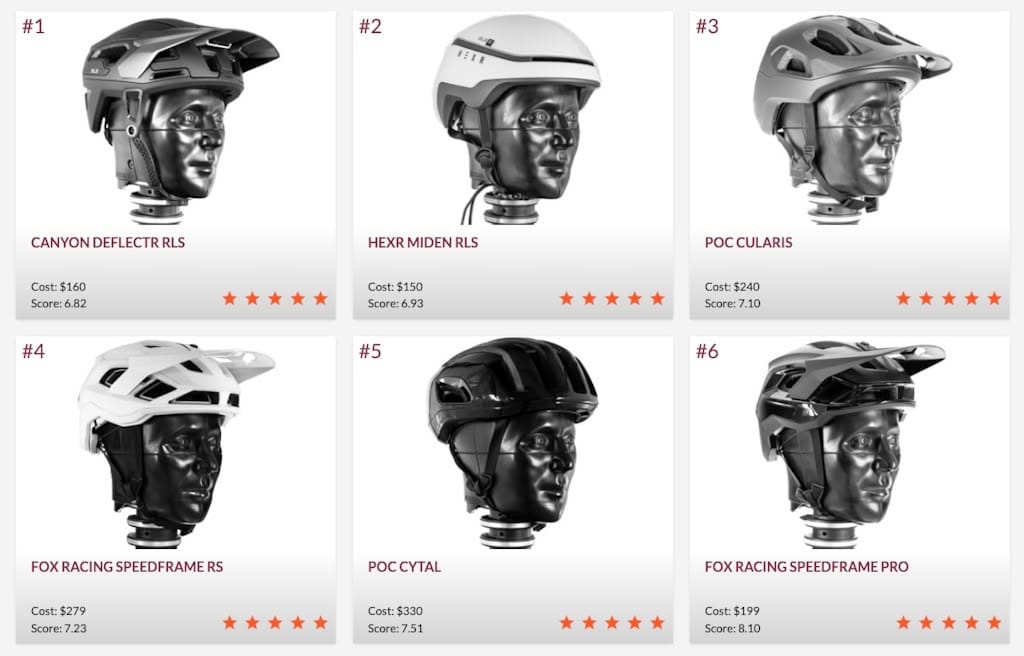

Its debut has been nothing short of spectacular. The first two helmets to feature the technology—the Canyon Deflectr RLS and the HEXR Miden RLS—have just taken over the #1 and #2 positions in Virginia Tech’s prestigious Bicycle Helmet Ratings, outperforming 279 other models. This instant validation signals a significant shift in helmet design and rider safety.

What is RLS and How Does It Work?

RLS is a patented technology that takes a novel, outside-in approach to managing rotational impacts. Unlike internal slip-liners, RLS integrates its safety system into the helmet's exterior. It consists of external shell panels that are mounted onto the helmet's main body using a layer of small polycarbonate bearings.

The system is designed to activate in milliseconds during an impact through a three-stage process the company calls React, Roll, and Release.

- React: A patented adhesive layer is engineered to react to a specific impact force, instantaneously releasing its grip.

- Roll: With the adhesive released, the external RLS panel is now free to roll across the polycarbonate bearings in any direction, redirecting harmful rotational energy away from the head.

- Release: The panel then detaches completely to further dissipate the impact energy, offering an additional layer of protection from concussive forces.

Interestingly, the concept was discovered almost by accident. Jamie Cook, the founder of RLS and co-founder of the 3D-printed helmet company HEXR, observed that the outer shell of a colleague's helmet released during a crash. This action was found to have significantly reduced the rotational forces. From this observation, RLS was born.

The Proof: Dominating the Test Results

The most compelling evidence for RLS's effectiveness comes from the independent, unbiased testing at the Virginia Tech helmet lab. The brand-new Canyon Deflectr RLS, a trail mountain bike helmet, earned the #1 ranking with an astonishingly low score of 6.82 (lower scores are better). The HEXR Miden RLS, an urban-focused helmet, secured the #2 spot with a score of 6.93.

These results are corroborated by further independent testing. According to RLS, research conducted by ICUBE at the University of Strasbourg—a world-leading biomechanics research center—found that RLS-equipped helmets reduced Peak Rotational Velocity by an average of 56% to 66% compared to identical helmets without the system. This translates to a staggering 68% to 84% reduction in the probability of a brain injury.

The First Helmets and a Lingering Question

The first wave of RLS-equipped helmets demonstrates the technology's versatility across different cycling disciplines.

- Canyon Deflectr RLS: A trail helmet set to retail for a very competitive $160 and expected to be available later this autumn.

- HEXR Miden RLS: An urban/commuter helmet priced at $150, with availability expected in October.

- HEXR Sifer: An aero road helmet planned for a Spring 2026 release at $250.

While the safety benefits are clear, the design does raise one minor environmental question: what happens to the small polycarbonate bearings when a panel releases? In impact test videos, the bearings appear to scatter along with the detached panel. While the panels are large enough to be recovered, the tiny bearings could easily be lost, creating a small amount of plastic litter as a trade-off for its state-of-the-art protection.

Even with this consideration, RLS technology represents a major leap forward. By deconstructing and redirecting impact forces before they reach the rider, it has set a new benchmark for safety. As RLS partners with more brands in the coming months, cyclists can look forward to a safer future on the road and trail.

For more information, visit releaselayer.com.