Keeping the Forged Canti Alive, 75 Pre-Orders at a Time

A quick look at the Rene Herse canti brakes, a 75g forged wonder, and why the company is turning to pre-orders to fund the next expensive batch.

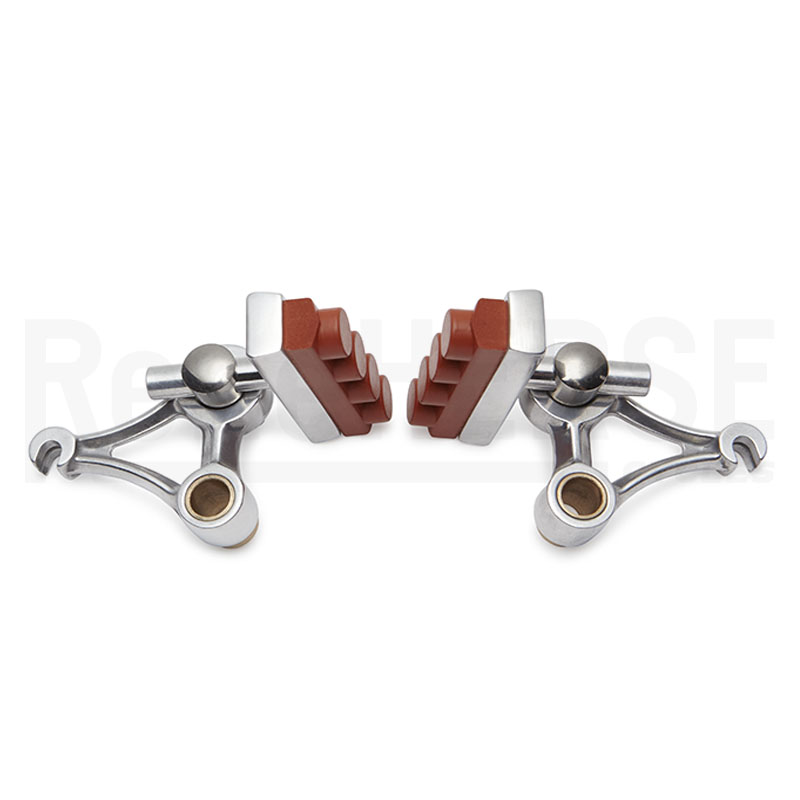

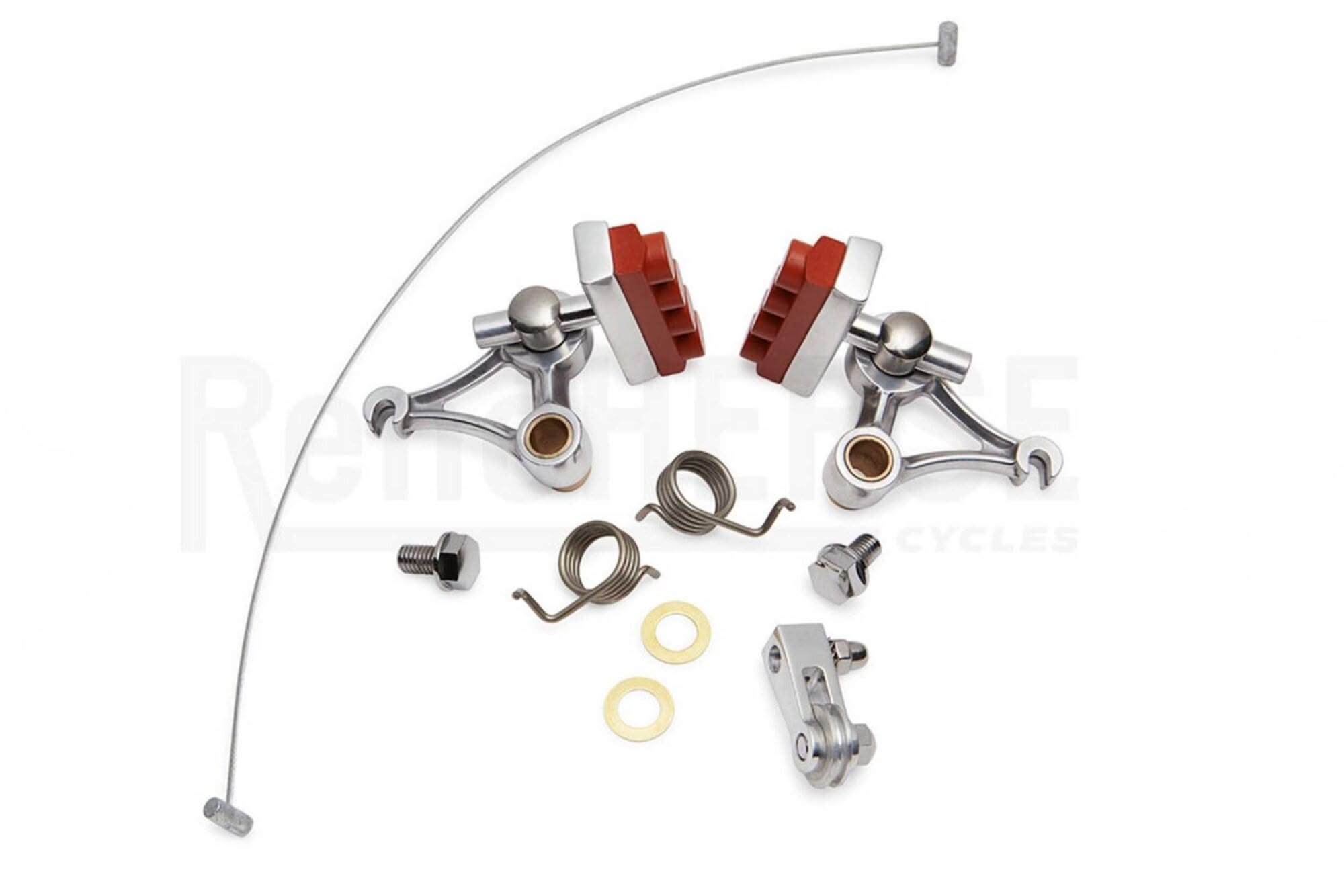

I find the economics of high-end component manufacturing fascinating. Take the Rene Herse cantilever brakes—they're essentially a "perfected" component, forged, incredibly light at 75 grams, and born from a Peter Weigle Concours de Machines project. But that level of refinement, especially using expensive forging dies, is a huge financial lift for a small company. So, to fund the next batch, Rene Herse is turning to pre-orders. They need 75 commitments by November 30 to pull the trigger.

It’s a very direct and transparent "put your money where your mouth is" approach, and I respect it. While the world has mostly moved to discs, there's a dedicated, discerning crowd (think Rivendell or Crust riders) who will argue, correctly, that a great rim brake is a beautiful and highly effective thing. This pre-order is more than just buying a part; it’s voting with your wallet to keep a specific kind of uncompromising, niche product alive. I'm curious to see if they hit the number.

A Few Key Specifications:

- Weight: 75g (per brake). This is astoundingly light and speaks to the no-compromise design philosophy.

- Construction: Forged Aluminum. This is the key—it's what makes them so strong and also what makes the production dies so expensive.

- Tire Clearance: Clears 56mm tires (or 42mm with fenders). This confirms they are modern cantis for all-road bikes, not just museum pieces.

- Warranty: 10-year warranty. A reassuring sign of confidence in the design and materials.